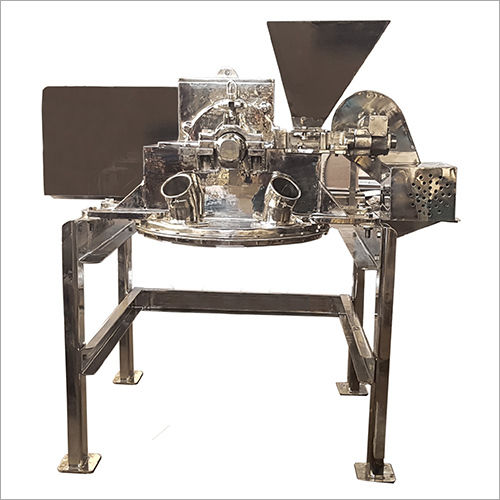

Arrangement for Grinding Liquids and Slurries

Arrangement for Grinding Liquids and Slurries Specification

- Equipment Type

- Industrial Grinding Arrangement

- Condition

- New

- Material

- Mild Steel

- Power Source

- Electricity

- Power(W)

- 2200 W

- Power Consumption

- 2.2 kW

- Dimension (L*W*H)

- 1000 mm x 450 mm x 1200 mm

About Arrangement for Grinding Liquids and Slurries

We take immense pleasure to introduce ourselves as one of the well established manufacturers and exporters of Arrangement for Grinding Liquids and Slurries. We have manufactured the grinding liquids and slurries making use of our state of the art machines as per set industry standards. We also offer the custom range of liquids and slurries to our clients as per their specifications. This product is known for its features like optimum performance, durability and easy installation. The Arrangement for Grinding Liquids and Slurries is highly preferred for recirculation of multi liquids and slurries.

Further Details:

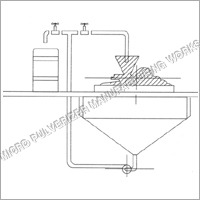

The circulating pump at the discharge of the lower hopper carries the material back to the feed of the Shubh Micro Pulverizer for repassing through the mill. When the grinding is finished the material is discharged into the drum or pumped to wherever desired.

Precision Grinding for Industrial Efficiency

Our grinding arrangement provides a powerful and efficient method for processing various liquids and slurries. With its robust mild steel construction and high-powered electric motor, it is designed to offer reliable, consistent results. Its easy integration into existing workflows makes it a top choice for industries focused on productivity and long-term durability.

Versatility & Durability Combined

The equipment is engineered for a wide range of applicationswhether in chemical, food processing, or allied industries. Its compact size allows for seamless installation, while mild steel ensures longevity even in demanding environments. With service and export support from India, customers receive expert guidance from installation through operation.

FAQs of Arrangement for Grinding Liquids and Slurries:

Q: How does the grinding arrangement for liquids and slurries operate?

A: This equipment uses a powerful 2.2 kW electric motor to drive the grinding process, efficiently reducing particle sizes in liquids and slurries. The robust mild steel build ensures reliable operation for continuous or batch production.Q: What types of industries benefit from this grinding arrangement?

A: Industries such as chemical processing, food production, pharmaceuticals, and wastewater treatment benefit from this arrangement, as it efficiently handles the preparation and homogenization of liquid and slurry mixtures.Q: When should one consider using this equipment for grinding needs?

A: You should opt for this arrangement when precise, consistent, and large-scale grinding of liquids or slurries is required. It is ideal for companies seeking to improve process efficiency and product uniformity.Q: Where can this equipment be installed?

A: With its manageable footprint (1000 mm x 450 mm x 1200 mm), the arrangement fits easily into most industrial environments, including factories, processing plants, and laboratory pilot setups.Q: What is the typical process for grinding using this arrangement?

A: The process involves feeding liquids or slurries into the equipment, where the electric-powered mechanism grinds materials to the desired consistency. The mild steel chamber ensures minimal contamination and maintains product quality.Q: How is the equipment maintained and serviced?

A: Regular inspection and cleaning are recommended to ensure longevity. As a manufacturer, exporter, and service provider, we offer ongoing support, spare parts, and technical guidance for seamless operation.Q: What are the main benefits of this grinding arrangement?

A: Major benefits include high operational efficiency, robust construction for long-term durability, minimal maintenance, and adaptability to various industrial tasks. The unit supports streamlined processing, enhancing productivity and quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Pulverizer Category

Shubh Micro Pulverizer No.2 Cgmp Model

Power(W) : 11 Horsepower (HP)

Power Source : Electric

Condition : New

Material : STAINLESS STEEL

Equipment Type : SEMI AUTOMATIC

Dimension (L*W*H) : L 66 * W 52 * H 60 Inch (in)

Gravity Feeding Micro Pulverizer

Power(W) : 2200 to 5600 W

Power Source : Electric

Condition : New

Material : Mild Steel

Equipment Type : Gravity Feeding Micro Pulverizer

Dimension (L*W*H) : 1500 x 600 x 1200 mm

MP-1GMP Pulverizer

Power(W) : 750 W

Power Source : Electric

Condition : New

Material : Stainless Steel

Equipment Type : Pulverizer

Dimension (L*W*H) : 600 mm x 450 mm x 1200 mm

Shubh Micro Pulverizer Ss Contact Parts

Power(W) : 1500 W 7500 W

Power Source : Electric

Condition : New

Material : Stainless Steel (SS) Contact Parts

Equipment Type : Micro Pulverizer

Dimension (L*W*H) : 550 mm x 450 mm x 1200 mm

Send Inquiry

Send Inquiry