Disc Pulverizer Plastic Grinding

Disc Pulverizer Plastic Grinding Specification

- Product Type

- pulverizer

- Power Source

- Electric

- Power(W)

- 7 Horsepower (HP)

- Color

- BLUE

Disc Pulverizer Plastic Grinding Trade Information

- FOB Port

- MUMBAI

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 5 Per Month

- Delivery Time

- 8 Week

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

About Disc Pulverizer Plastic Grinding

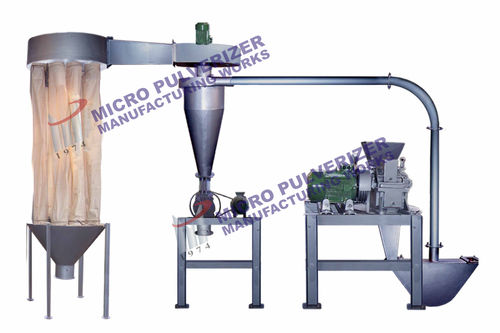

Flexible Designenables alteration of the System as per Space Available.

SHUBH MICRO DISC PULVERIZER (FOR PLASTIC GRINDING)Â

MODEL NO. SMDP - 305

| Grinding Chamber: | Segmented Disc Dai. 305mm made out of 60 nos. of sharp hardened segments |

| Feeding             : | Wide and smooth finished M.S. Feed Hopper. Provided with Vibro feeder to control the feed. |

| Rotor Assembly: | EN-8 Rotor Shaft heavy duty Ball Bearings at both ends. |

| PowerRequired: | 30 H.P. Electric Motor for rotor drive 2 H.P. for rotary valve 5 H.P. Crompton make Electric Motor for Blower. |

| Discharge           : | Pulverized material is passed through cyclone and collected below the Rotary Air Lock.Hot air is discharged through blower outlet. |

| Accessories: | Set of tools to remove the disc or to adjust the gap between the disc. |

ADVANTAGES

Total Dust Free Environment.

Increase in output capacity.

Labour Savings.

Guaranteed Performance.

Compact and Highly Efficient.

Uniform production.

Â

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Pulverizer Category

Plastic Pulverizer With Pneumatic System

Power Source : Electric

Power(W) : 17 31 69.5 Horsepower (HP)

Dimension (L*W*H) : 12 X 6 X 12 Foot (ft)

Condition : New

Material : MS / SS CONTACT PARTS / CGMP

PVC Pipe Pulverizer

Power Source : Electric

Power(W) : 40 HP

Dimension (L*W*H) : 1950 mm x 1500 mm x 2000 mm

Condition : New

Material : Mild Steel

Power Consumption : 4560 kg/hr

Send Inquiry

Send Inquiry