Centrifugal Sieving Machine

Centrifugal Sieving Machine Specification

- Type

- Centrifugal Sieving Machine

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Frequency (MHz)

- 50 Hz

- Size

- Medium to Large, customizable

- Width

- Depends on model

- Dimension (L*W*H)

- 1200 x 600 x 1000 mm (approx.)

About Centrifugal Sieving Machine

Centrifugal Sieving Machine

Backed with expertise and knowledge in the domain, we are counted amongst the foremost manufacturers and exporters of Centrifugal Sieving Machine. We have engineered the range of sieving machine using top notch quality materials as per set industry standards. Offered range of sieving machine is widely appreciated due to its features such as high efficiency, hassle free operation and low maintenance. Centrifugal Sieving Machine is widely used in food, chemical and mineral industries for mixing, blending and sieving purposes.

Advanced Stainless Steel Build

Our centrifugal sieving machines stainless steel construction ensures both durability and compliance with strict hygienic standards. This makes it a top choice for food, pharmaceutical, and chemical industries that require a contamination-free sieving process. Its resistance to corrosion extends machine life even in demanding environments.

Automatic and Customizable Operation

Engineered for automatic functionality, this sieving machine minimizes manual involvement and allows for consistent, high-throughput processing. Each model can be customized to suit specific applications, with size and width tailored to your operational requirements.

FAQs of Centrifugal Sieving Machine:

Q: How does the centrifugal sieving machine operate?

A: The machine works by using centrifugal force generated by a rotating screen basket. Material is fed into the center of the machine and pushed outwards, where fine particles pass through the screen and oversized materials are discharged separately.Q: What materials can be processed using this centrifugal sieving machine?

A: This sieving machine is suitable for a wide range of materials, including powders, granules, and slurry-based products. It is commonly used in food, chemical, pharmaceutical, and other process industries that require fine separation or filtration.Q: When should a company consider using a centrifugal sieving machine?

A: A centrifugal sieving machine is recommended when efficient, high-capacity, and hygienic sieving is required, especially in applications needing to minimize manual handling and improve product consistency.Q: Where is this machine manufactured and exported from?

A: We manufacture and export the centrifugal sieving machine from India, catering to global markets with our high-quality, customizable solutions.Q: What is the process involved in centrifugal sieving?

A: Raw material is fed into the machines inlet. The rotating screen uses centrifugal force to separate finer particles through the mesh, while coarser residues are collected at a separate output. The entire operation is automated, requiring minimal manual supervision.Q: How can the size and width of the machine be customized?

A: As a manufacturer, we offer flexible customization options. The machines width and overall dimensions can be adjusted during production to match specific space and output requirements.Q: What benefits does this centrifugal sieving machine offer?

A: The machine delivers efficient separation, reduces labor through automatic operation, and ensures product hygiene due to its stainless steel construction. Its also energy-efficient, durable, and adjustable to your process needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Sieving Machine Category

Pharmaceutical Ball Mill CGMP

Type : Ball Mill

Dimension (L*W*H) : 1860 mm x 1350 mm x 1435 mm (customizable)

Material : Stainless Steel

Frequency (MHz) : 50 Hz

Voltage : 220440 V

Computerized : No

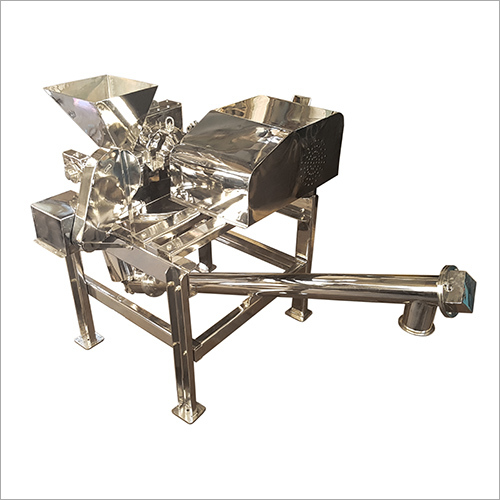

MP-2 With Screw Conveyor

Type : Screw Conveyor

Dimension (L*W*H) : 1200x800x900 mm

Material : Stainless Steel

Frequency (MHz) : 50/60 Hz

Voltage : 220V

Computerized : No

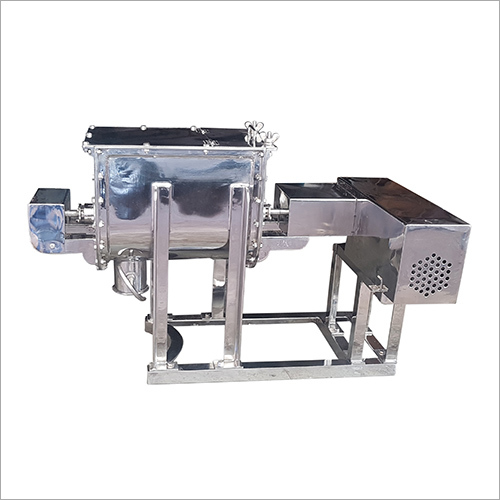

Lab Ribbon Blender CGMP

Type : Ribbon Blender

Dimension (L*W*H) : 700 x 500 x 800 mm

Material : Stainless Steel SS316/SS304

Frequency (MHz) : 50 Hz

Voltage : 220V240V

Computerized : No

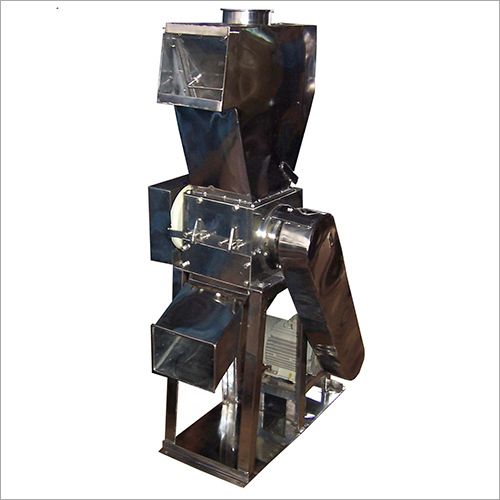

Pharmaceutical Crusher CGMP

Type : Pharmaceutical Crusher CGMP

Dimension (L*W*H) : 750 mm x 500 mm x 1200 mm

Material : Stainless Steel

Frequency (MHz) : 50 Hz

Voltage : 220 V

Computerized : No

Send Inquiry

Send Inquiry