Pharmaceutical Ball Mill CGMP

Pharmaceutical Ball Mill CGMP Specification

- Type

- Ball Mill

- Material

- Stainless Steel

- Capacity

- 5 kg to 500 kg per batch (customizable)

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 220-440 V

- Frequency (MHz)

- 50 Hz

- Size

- Customizable

- Width

- Customizable

- Weight

- 800 kg (approx., varies with capacity)

- Dimension (L*W*H)

- 1860 mm x 1350 mm x 1435 mm (customizable)

- Warranty

- 1 Year

- Finishing

- Mirror/Matte Polish (CGMP Standard)

- Compliance

- CGMP, CE Certified

- Drive Type

- Gear Motor Driven

- Drum Material Thickness

- 8 mm to 12 mm (as per requirement)

- Discharge Mode

- Manual/Valve Type

- Application

- Pharmaceutical, Chemical, Food Industries

- Power Consumption

- 7.5 HP to 30 HP (depending on model)

- Safety Features

- Emergency Stop, Interlocks Provided

- Noise Level

- Low

Pharmaceutical Ball Mill CGMP Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 10-15 Days

About Pharmaceutical Ball Mill CGMP

This high performance pharmaceutical ball mill is used for homogenous mixing and blending of medicinal substances under controlled temperature range. Known for its large processing volume, this machine is capable of handling dry as well as wet substances. Usually, this machine is suitable for materials of medium hardness or size is used for grinding into fine powder form. This machine has ergonomic sieve ( with around 1000 pores) through which slurry or powder passes. Long working life, high output and long lasting quality are the key aspects of this centrifugal system.

Specification

| MOC | MS/SS-304/SS316/CGMP |

| Motor Power | 1.5 HP |

| Volumetric Capacity | 75 (liter) |

| Size | 1.5' X 1.5' |

| Brand | Shubh |

| Shape | Cycindrical |

CGMP & CE Compliant Construction

Manufactured in India, this ball mill complies with international CGMP and CE certification, ensuring it meets the strictest hygiene, safety, and operational standards. The stainless steel drum, with a thickness of 8 mm to 12 mm, is designed for durability and resistance to contamination, making it ideal for regulated industries.

Flexible Capacity & Customization

Catering to operations of varied scales, this ball mill supports batch sizes ranging from 5 kg up to 500 kg. Both the overall dimensions (L*W*H), and the width are customizable to fit specific production layouts, optimizing space and efficiency within your facility.

Efficient, Safe Operation

Equipped with a gear motor drive and integrated safety features, including emergency stop buttons and interlocks, the ball mill operates smoothly with low noise. Manual or valve discharge options offer controlled material output, while automatic grade functionality simplifies operation.

FAQs of Pharmaceutical Ball Mill CGMP:

Q: How does the Pharmaceutical Ball Mill support CGMP and CE compliance?

A: The ball mills construction adheres strictly to Current Good Manufacturing Practices (CGMP) and is CE certified, meaning all materials, finishes, safety features, and design processes meet international standards for pharmaceutical equipment.Q: What materials are used for the drum, and how is thickness determined?

A: The drum is made of stainless steel with thickness ranging from 8 mm to 12 mm. The exact thickness is selected based on client requirements, batch size, and specific industrial applications to ensure durability and safety.Q: When should the ball mills emergency stop and interlocks be used?

A: Emergency stop and interlocks should be activated in situations requiring immediate cessation of machine operation, such as equipment malfunction, safety hazards, or maintenance interventions, ensuring operator and process protection.Q: Where can this ball mill be installed, and can its size be tailored?

A: The ball mill is designed for installation in pharmaceutical, chemical, and food processing plants. Its dimensions and width are customizable to accommodate specific spatial constraints within facilities across India and abroad.Q: What is the operational process for batch discharge?

A: The mill offers two discharge modes: manual and valve type. After grinding, operators can manually unload the batch or utilize the valve for controlled and safe discharge, depending on process requirements.Q: How does low noise operation benefit industrial environments?

A: Low noise from gear motor-driven operation creates a safer, more comfortable workplace, reducing auditory fatigue and promoting clear communication between staff members during production cycles.Q: What is the warranty and support available for this ball mill?

A: Manufactured and exported from India, the ball mill comes with a one-year warranty, covering manufacturing defects. Additional support, installation guidance, and service are provided to ensure uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Sieving Machine Category

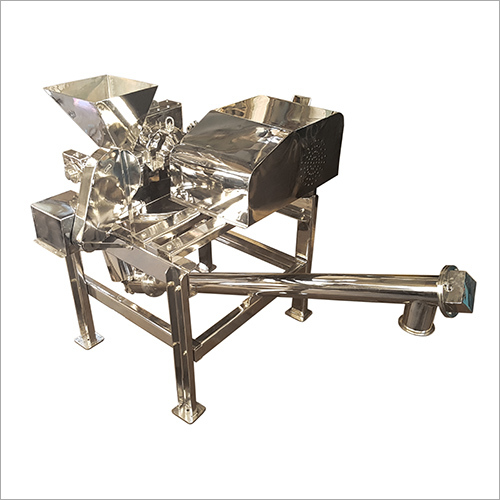

MP-2 With Screw Conveyor

Material : Stainless Steel

Type : Screw Conveyor

Dimension (L*W*H) : 1200x800x900 mm

Automatic Grade : SemiAutomatic

Size : Standard

Computerized : No

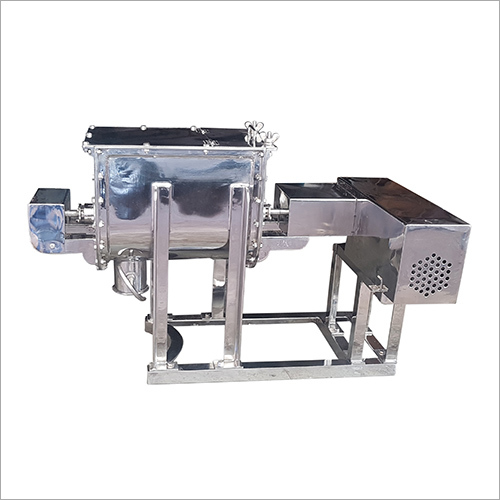

Lab Ribbon Blender CGMP

Material : Stainless Steel SS316/SS304

Type : Ribbon Blender

Dimension (L*W*H) : 700 x 500 x 800 mm

Automatic Grade : SemiAutomatic

Size : Compact

Computerized : No

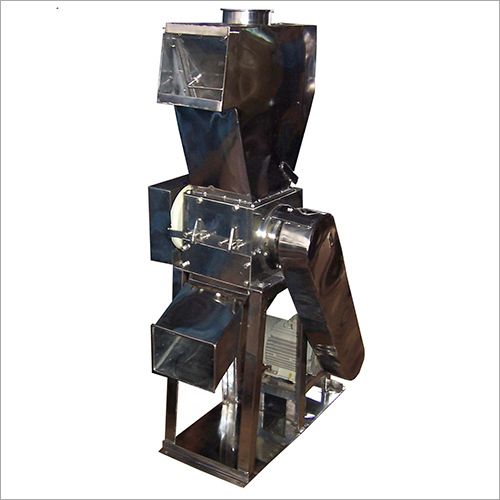

Pharmaceutical Crusher CGMP

Material : Stainless Steel

Type : Pharmaceutical Crusher CGMP

Dimension (L*W*H) : 750 mm x 500 mm x 1200 mm

Automatic Grade : SemiAutomatic

Size : Medium

Computerized : No

Centrifugal Sieving Machine

Material : Stainless Steel

Type : Centrifugal Sieving Machine

Dimension (L*W*H) : 1200 x 600 x 1000 mm (approx.)

Automatic Grade : Automatic

Size : Medium to Large, customizable

Computerized : No

Send Inquiry

Send Inquiry