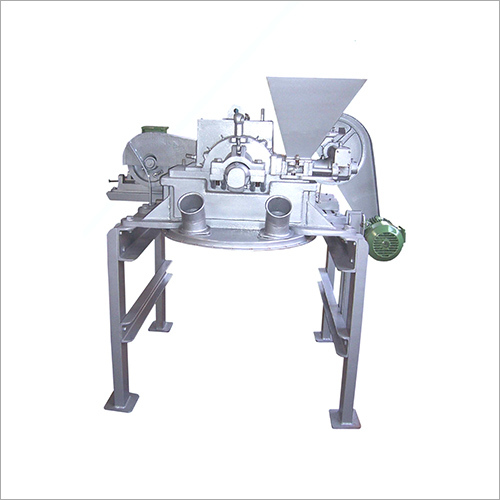

Coal Pulverizer

Coal Pulverizer Specification

- Equipment Type

- Coal Pulverizer

- Condition

- New

- Material

- Mild Steel

- Power Source

- Electric

- Power(W)

- 12000 W

- Power Consumption

- 12 KW

- Dimension (L*W*H)

- 500mm x 750mm x 900mm

- Usage/Application

- Industrial Coal Grinding

- Capacity

- 300 kg/hr

- Feed Size

- Up to 15 mm

- Output Size

- 200 Mesh

- Automation Grade

- Semi-Automatic

- Weight

- 650 kg

- Voltage

- 380V

- Frequency

- 50 Hz

- Finishing

- Paint Coated

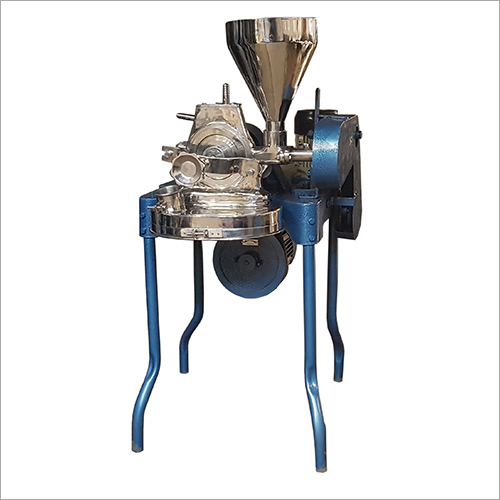

About Coal Pulverizer

Specification

| Capacity | 15 to 20 Kgs per hour 100% passing Through 212 Micron or 723 BSS mesh |

| MOC | Contact Parts SS -316 |

| Model | Baby |

| Brand | Shubh |

| Is It Need AMC | Not Need AMC |

| Power | 2 H.P for Grinding 0.5 H.P. for Feeding Total 2.5 H.P. |

| Phase | 3 Phase |

Precision Grinding for Industrial Coal Processing

Optimize your operations with our semi-automatic Coal Pulverizer, designed for consistent grinding performance in industrial settings. The pulverizer's advanced engineering ensures uniform processing of coal to a fine 200 mesh output, enabling superior combustion and energy efficiency. With a capacity of 300 kg/hr and paint-coated mild steel construction, this equipment delivers both robustness and reliability to your manufacturing processes.

Engineered for Efficiency and Reliability

Built to handle demanding industrial environments, this Coal Pulverizer features a 12 KW electric motor and supports continuous use. Its semi-automatic mechanism simplifies operations, while the carefully designed feed and output system accommodates coal pieces up to 15 mm and delivers reliably fine results. Backed by robust construction and quality finishing, it stands as a dependable solution for manufacturers and exporters.

FAQ's of Coal Pulverizer:

Q: How does the semi-automatic coal pulverizer work in industrial coal grinding applications?

A: The coal pulverizer operates using a semi-automatic control system, where the primary grinding process is performed mechanically. Coal is fed up to a 15 mm size, and it is processed into fine powder (200 mesh) at a rate of up to 300 kg/hr. The equipment is powered by a 12 KW electric motor, providing consistent and efficient operation for industrial coal preparation.Q: What are the main benefits of using this coal pulverizer in manufacturing plants?

A: Key benefits include high processing capacity (300 kg/hr), precise output size (200 mesh), energy efficiency with 12 KW power consumption, and durable construction using mild steel with a paint-coated finish. These features ensure reliable, low-maintenance operation and improved fuel combustion efficiency in industrial environments.Q: When and where should this coal pulverizer be deployed for optimal performance?

A: This coal pulverizer is best suited for industrial settings that require continuous and uniform coal grinding, such as power generation plants, cement production, and other manufacturing sectors. It operates efficiently when installed in environments with a stable electric supply (380V, 50Hz) and requires suitable ventilation and safety measures for dust control.Q: What is the installation process for this equipment, considering its size and weight?

A: Installation requires a dedicated space due to its compact dimensions (500mm x 750mm x 900mm) and weight (650 kg). Placement on a stable, level surface with proper electrical connections (380V, 12KW) is essential. Manufacturer-provided guidance ensures safe assembly and setup, including securing the unit and integrating it with pre-existing material handling systems.Q: How can the equipment's semi-automatic operation reduce manual labor?

A: The semi-automatic design automates key aspects of coal feeding and grinding, minimizing manual intervention. Operators primarily need to load the coal and monitor the process, which reduces labor intensity and the risk of human error while maintaining consistent output quality.Q: What safety and maintenance measures are recommended for ongoing operation?

A: Routine cleaning, checking for wear in moving parts, ensuring proper lubrication, and periodic inspection of electrical connections are vital for longevity and safe operation. Users should follow manufacturer guidelines for dust management and wear protective gear to mitigate exposure to fine coal particles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Pulverizer Category

Ball Mill Big MICRO PULVERIZER

Minimum Order Quantity : 01 Unit

Power Source : Electric

Equipment Type : Ball Mill Big MICRO PULVERIZER

Power(W) : 10 HP to 50 HP

Dimension (L*W*H) : As per customer requirement

Power Consumption : Low

Micro Pulverizer with Pneumatic System

Minimum Order Quantity : 01 Unit

Power Source : Electric

Equipment Type : Micro Pulverizer with Pneumatic System

Power(W) : 1500 W 15000 W

Dimension (L*W*H) : Customizable as per model/configuration

Power Consumption : 2 HP to 20 HP (varies by model)

Gravity Feeding Micro Pulverizer

Minimum Order Quantity : 01 Unit

Power Source : Electric

Equipment Type : Gravity Feeding Micro Pulverizer

Power(W) : 2200 to 5600 W

Dimension (L*W*H) : 1500 x 600 x 1200 mm

Power Consumption : 3 to 7.5 HP

Shubh Micro Pulverizer Ms

Power Source : Electric

Equipment Type : Micro Pulverizer

Power(W) : 1500 W

Dimension (L*W*H) : 500 mm x 450 mm x 900 mm

Power Consumption : 2 HP

Send Inquiry

Send Inquiry