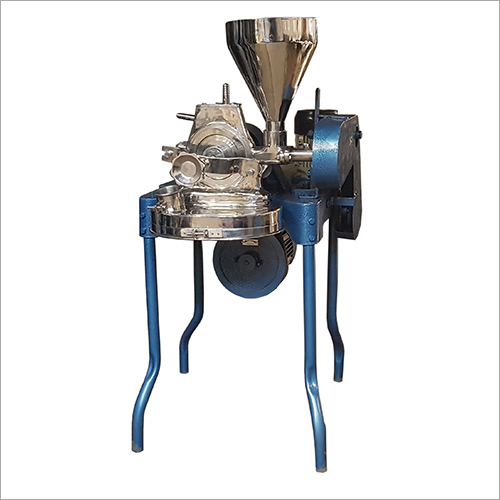

Micro Pulverizer with Pneumatic System

Micro Pulverizer with Pneumatic System Specification

- Equipment Type

- Micro Pulverizer with Pneumatic System

- Condition

- New

- Material

- Mild Steel/Stainless Steel

- Power Source

- Electric

- Power(W)

- 1500 W 15000 W

- Power Consumption

- 2 HP to 20 HP (varies by model)

- Dimension (L*W*H)

- Customizable as per model/configuration

Micro Pulverizer with Pneumatic System Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Delivery Time

- Days

- Packaging Details

- Wooden Packaging

- Main Export Market(s)

- Middle East, Western Europe, Africa, Central America, South America, Asia, Eastern Europe, North America, Australia

- Main Domestic Market

- All India

About Micro Pulverizer with Pneumatic System

Micro Pulverizer with Pneumatic System

Blessed & supported by the team of adroit professionals, our company is considered as one of the eminent manufacturers and exporters of Micro Pulverizer with Pneumatic System. The machine is broadly used in food, pharmaceutical and mineral industry for varied applications such as to grind chemicals, spices, concrete and food items. Our respected patrons is widely appreciating the range of Micro Pulverizer with Pneumatic System due to its salient features low power consumption, easy usage and guaranteed performance.

Advantages

- Total Dust Free Environment

- Increase in Output Capacity

- Labour Savings

- Compact & Highly Efficient

- Uniform Production.

Precision Grinding for Versatile Applications

Engineered for flexibility, the Micro Pulverizer with Pneumatic System is designed to handle a variety of materials. Its powerful electric motor and customizable sizing make it well-suited for industrial sectors seeking granular consistency and efficient material handling. Choose between mild steel and stainless steel models to match your operational needs.

Efficient Material Handling with Pneumatic Technology

This pulverizer utilizes an integrated pneumatic system, ensuring effective material conveyance and reduced dust formation. The pneumatic feature enhances the automation of the grinding process, leading to improved output, reduced downtime, and safer work environments. The result is a cleaner and more efficient production flow.

FAQs of Micro Pulverizer with Pneumatic System:

Q: How does the pneumatic system in the Micro Pulverizer improve efficiency?

A: The integrated pneumatic system actively removes ground material from the pulverizing chamber, which prevents clogging, reduces dust, and streamlines the discharge process. This results in steadier output, minimal manual intervention, and overall enhanced operational efficiency.Q: What materials can be processed using this Micro Pulverizer?

A: This equipment is suitable for grinding a wide range of bulk solids, including but not limited to spices, minerals, chemicals, plastic granules, and pharmaceutical ingredients. The choice of mild steel or stainless steel construction ensures compatibility with various types of materials.Q: When should I consider customizing the dimensions of the Micro Pulverizer?

A: Customization is recommended when your processing capacity, available installation space, or specific material requirements demand a non-standard configuration. Custom dimensions can optimize machine performance for your unique production setup.Q: Where is the Micro Pulverizer with Pneumatic System manufactured and exported from?

A: The equipment is manufactured and exported from India by a reputable exporter and service provider with extensive expertise in industrial pulverizers and related machinery.Q: What is the process of operating the Micro Pulverizer with Pneumatic System?

A: Operation involves feeding the material into the hopper, where it is pulverized in the grinding chamber. The pneumatic system then conveys the processed material to a cyclone or collection bin, making continuous operation seamless and efficient.Q: What are the main benefits of using this Micro Pulverizer with Pneumatic System?

A: Key advantages include superior grinding consistency, automated material conveyance, minimal dust, and high output rates. The electric-powered system ensures reliable operation with options suitable for small to large-scale production.Q: How much power does this equipment consume during operation?

A: Power consumption varies by model, ranging from 2 HP (1500 W) for smaller units to 20 HP (15000 W) for larger models. This allows users to select a model that best fits their processing capacity and energy requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Pulverizer Category

Liner Micro Pulverizer

Material : Stainless Steel

Power(W) : 3000 W

Condition : New

Power Source : Electric

Power Consumption : 3 kW

Dimension (L*W*H) : 1200 mm x 800 mm x 1800 mm

MP-1GMP Pulverizer

Material : Stainless Steel

Power(W) : 750 W

Condition : New

Power Source : Electric

Power Consumption : Single Phase 1 HP

Dimension (L*W*H) : 600 mm x 450 mm x 1200 mm

Shubh Micro Pulverizer No.5 Mp-5

Material : Mild Steel

Power(W) : 1500 W

Condition : New

Power Source : Electric

Power Consumption : 2 HP

Dimension (L*W*H) : 610 mm x 375 mm x 850 mm

Coal Pulverizer

Material : Mild Steel

Power(W) : 12000 W

Condition : New

Power Source : Electric

Power Consumption : 12 KW

Dimension (L*W*H) : 500mm x 750mm x 900mm

Send Inquiry

Send Inquiry