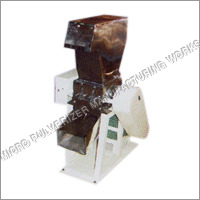

Grinder Pre-Crusher

Grinder Pre-Crusher Specification

- Frequency

- 50/60 Hz

- Phase

- Three Phase

- Noise Level

- Low

- Temperature

- Ambient

- Material

- Mild Steel / Stainless Steel

- Capacity

- 50 kg/hr to 5000 kg/hr

- Computerized

- No

- Control Mode

- Manual

- Power

- 3 HP to 60 HP

- Dimension (L*W*H)

- 1200 x 800 x 1500 mm (varies by model)

- Color

- Blue / Green / Customized

Grinder Pre-Crusher Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Delivery Time

- Days

- Packaging Details

- Wooden Packaging

- Main Export Market(s)

- Asia, Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America

- Main Domestic Market

- All India

About Grinder Pre-Crusher

We are specialized in manufacturing and exporting a wide range of Grinder Pre-Crusher. It is robustly constructed as per industry standard so as to maintain the optimum level productivity. Our skilled teams of professionals have certified the pre-crusher on several safety parameters, before final dispatch. The Grinder Pre-Crusher is known for its features like longer service life, optimum performance and easy operation. Further, this pre-crusher finds wide usage in grinding herbs, chemicals, spices and many more.

Specifications:

| MODEL | CHAMBER | HP |

| SG-1 | 4" | 3/4 |

| SG-2 | 6" | 1 |

| SG-3 | 8" | 2 |

| SG-4 | 10" | 3 |

| SG-5 | 12" | 5 |

| SG-6 | 15" | 7.5 |

| SG-7 | 15" | 10 |

| SG-8 | 18" | 15 |

| SG-9 | 20" | 20 |

| SG-10 | 22" | 20 |

| SG-11 | 24" | 25 |

Robust Construction and Adaptable Capacity

Engineered from mild steel or stainless steel, the Grinder Pre-Crusher can handle various materials with a wide capacity range, from 50 kg/hr to 5000 kg/hr. Its built-to-last structure ensures reliable performance in demanding operational settings, while adaptability meets diverse industry needs.

Versatile Power and Control Options

With manual control and power options from 3 HP up to 60 HP, operators have direct command over process efficiency. Its compatibility with three-phase power and both 50 and 60 Hz frequencies also allows for seamless integration into existing production facilities.

Customized Solutions for Every Industry

The pre-crusher is available in standard blue or green finishes, with custom color options to align with organizational branding or requirements. Its dimensions are flexible, ensuring an optimal fit for varying plant layouts and operational demands.

FAQs of Grinder Pre-Crusher:

Q: How is the Grinder Pre-Crusher operated and controlled?

A: The Grinder Pre-Crusher operates on a manual control mode, allowing the user to directly adjust operational settings during processing, ensuring precise handling and minimal complexity.Q: What kind of materials can be processed with this Grinder Pre-Crusher?

A: Constructed from mild steel or stainless steel, the pre-crusher is suitable for handling a variety of industrial materials, ranging from bulk solids to granules, depending on specific usage requirements.Q: When should I use the Grinder Pre-Crusher in my processing line?

A: It is ideal for use at the initial stage of size reduction, before downstream grinding or milling operations. Employ the pre-crusher when large raw materials require preliminary crushing to smooth production flow and enhance efficiency.Q: Where is the Grinder Pre-Crusher commonly utilized?

A: This equipment is widely found in manufacturing plants, processing units, food industries, and chemical facilities across India, wherever robust material pre-crushing is essential.Q: What is the process for installing and integrating the Grinder Pre-Crusher?

A: The pre-crusher requires placement in a designated area compatible with its three-phase, 50/60 Hz power supply. Installation guidelines recommend ensuring proper alignment, securing connections, and adhering to safety protocols for optimal performance.Q: How does using this pre-crusher benefit my operation?

A: Utilizing the Grinder Pre-Crusher improves throughput, initial material breakdown, and reduces manual labor. Its low noise and ambient temperature operation help create a safer workplace while enhancing productivity and process reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre-Crusher Category

Pharmacuetical Crusher

Minimum Order Quantity : 01 Unit

Computerized : No

Usage & Applications : Crushing and grinding pharmaceutical materials

Frequency : 50 Hz

Material : Stainless Steel

Dimension (L*W*H) : 700 x 320 x 830 mm

Send Inquiry

Send Inquiry