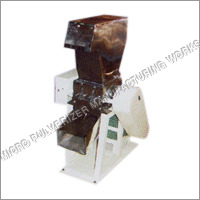

Pharmacuetical Crusher

MOQ : 01 Unit

Pharmacuetical Crusher Specification

- Noise Level

- Low

- Usage & Applications

- Crushing and grinding pharmaceutical materials

- Phase

- Single Phase

- Features

- Corrosion-resistant body, easy operation, high efficiency crushing

- Frequency

- 50 Hz

- Temperature

- Ambient

- Type

- Pharmaceutical Crusher

- Material

- Stainless Steel

- Capacity

- 10-100 kg/hr

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220 V

- Power

- 2 HP

- Weight (kg)

- 55 kg

- Dimension (L*W*H)

- 700 x 320 x 830 mm

- Color

- Silver

- Output Fineness

- Up to 100 mesh

- Mobility

- Mounted on wheels for ease of movement

- Safety Features

- Overload protection, emergency stop switch

- Body Finish

- Mirror Polished

- Crushing Chamber Type

- Enclosed with safety lid

- Feed Size

- Up to 20 mm

- Cleaning

- Easy to disassemble for cleaning

- Application Industries

- Pharmaceutical, Chemical, and Food Industries

- Blade Type

- Hardened stainless steel cutter blades

Pharmacuetical Crusher Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Packaging Details

- Wooden Packaging

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Africa, Middle East, South America, Asia, Central America, North America

- Main Domestic Market

- All India

About Pharmacuetical Crusher

Offered pharmaceutical crusher is useful for effective crusher is useful for effective crushing of medical waste to avoid secondary pollution or cross contamination. This machine is perfect for crushing of disposable saline bottle and tubes, syringers, vials and other medical garbage. This machine has multiple blades, feeder with adequate width, powerful motor and high strength shaft that are fitted by maintaining equal distance from each other. This pharmaceutical crusher is well known for its environment friendly mechanism , low noise and vibration generation level, perfect diameter and long working life.

Superior Safety and Hygiene Design

This crusher features an enclosed crushing chamber with a safety lid, overload protection, and an emergency stop switch, ensuring operational safety. The mirror-polished stainless steel body resists corrosion and supports GMP-compliant cleaning, making it suitable for pharmaceutical, chemical, and food processing environments.

Efficient and High-Quality Crushing

Equipped with hardened stainless steel cutter blades and a powerful 2 HP motor, the crusher delivers high-efficiency performance. Material can be ground to a fine powder up to 100 mesh. With a feed size capacity of up to 20 mm and output ranging from 10 to 100 kg/hr, it meets a variety of industrial-scale demands.

User-Friendly Operation and Maintenance

Designed for manual control and ease of use, the crusher can be swiftly maneuvered thanks to its mounted wheels. It is easy to disassemble, making routine cleaning straightforward. Its low noise level and straightforward operation minimize disruptions within production environments.

FAQs of Pharmacuetical Crusher:

Q: How does the enclosed crushing chamber with safety lid enhance operator safety?

A: The enclosed crushing chamber and safety lid prevent direct contact with moving parts during operation, reducing the risk of injury. Combined with overload protection and an emergency stop switch, the design prioritizes user safety throughout the crushing process.Q: What materials and particle sizes can be processed using this pharmaceutical crusher?

A: This crusher is engineered for use with a wide range of pharmaceutical, chemical, and food materials. It can handle feed sizes up to 20 mm and reduce them to a fine powder of up to 100 mesh, making it suitable for various production requirements.Q: When is it necessary to clean the crusher, and how is it accomplished?

A: Regular cleaning is recommended after each batch or shift to maintain hygiene and prevent cross-contamination. The crusher can be easily disassembled, allowing thorough access to internal components for efficient cleaning and sanitization.Q: Where can this crusher be used within industrial settings?

A: The crusher is designed for pharmaceutical, chemical, and food industries. Its mobility, ensured by wheels, allows easy relocation between workstations or process areas within a facility as operational needs dictate.Q: What is the process for operating this crusher, and is specialized training required?

A: Operation is straightforward and manual, with intuitive controls for starting and stopping. While no specialized training is required, familiarization with safety protocols and cleaning procedures is recommended for optimal and safe use.Q: How does the corrosion-resistant stainless steel body benefit users?

A: The stainless steel construction offers high resistance to corrosion, extending equipment life and ensuring compliance with hygiene standards. The mirror-polished finish also simplifies cleaning and reduces the risk of contamination.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pre-Crusher Category

Grinder Pre-Crusher

Minimum Order Quantity : 1 Unit

Phase : Three Phase

Capacity : 50 kg/hr to 5000 kg/hr

Noise Level : Low

Control Mode : Manual

Power : 3 HP to 60 HP

Send Inquiry

Send Inquiry