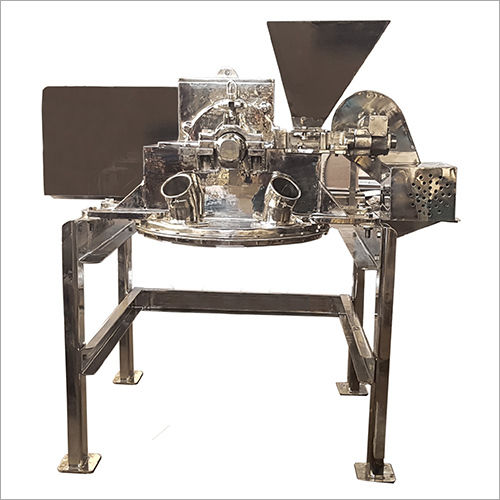

Micro Pulverizer Beater

Micro Pulverizer Beater Specification

- Equipment Type

- Pulverizer Beater / Hammer

- Condition

- New

- Power Source

- Mechanical / Electrical

- Power(W)

- As per machine design

- Power Consumption

- Depends on equipment capacity

- Dimension (L*W*H)

- As per requirement / standard or customized sizes

Micro Pulverizer Beater Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Delivery Time

- Days

- Packaging Details

- Wooden Packaging

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Micro Pulverizer Beater

Micro Pulverizer-Beater

Holding years of experience and knowledge in the particular industry, our company has been able to mark its strong presence in the market as one of the most excellent manufacturers and exporters of Micro Pulverizer-Beater. At our premises, we make emphasis on manufacturing quality range of industrial machines as per international standards. Owing to high performance, easy operation and low maintenance, this Micro Pulverizer-Beater is highly demanded in the market.

Further Details:

This are set of Micro Pulverizer-Beater revolving at high velocity in the chamber & beat in the materials as it enters from the screw feeders. These hammers are forged out of hardened material. Shubh micro also offers serrated type beaters for heat sensitive materials.

Optimized for Industrial Pulverizing

Our Micro Pulverizer Beaters are crafted to deliver superior grinding and crushing efficiency in diverse manufacturing environments. Each beater is tailored to your specifications, supporting both standard and custom sizes to ensure seamless integration. As reliable exporters and service providers, we guarantee consistent quality and expert technical assistance for installations throughout India and internationally.

Customized for Performance & Durability

Every pulverizer beater is meticulously designed to match machine requirements, optimizing power consumption and operational longevity. Whether powered mechanically or electrically, these beaters withstand rigorous use and maintain performance. Advanced manufacturing ensures low maintenance and high output, making them ideal for various material processing industries.

FAQs of Micro Pulverizer Beater:

Q: How is the Micro Pulverizer Beater customized to suit different equipment?

A: The Micro Pulverizer Beater can be manufactured in standard or customized dimensions (L*W*H) as per your specific equipment requirements. This ensures compatibility and optimal functionality in diverse pulverizing setups.Q: What power source options are available for this pulverizer beater?

A: Depending on your operational setup, the beater supports both mechanical and electrical power sources. The choice can be specified during ordering to match your existing equipment.Q: When should I replace my pulverizer beater for maximum efficiency?

A: It is recommended to replace the beater when there is noticeable wear or decrease in equipment performance. Regular inspections, following manufacturer guidelines, help ensure continuous efficient operation.Q: Where are these micro pulverizer beaters manufactured and exported from?

A: All Micro Pulverizer Beaters are produced in India by experienced manufacturers who also provide export services and technical support for global clients.Q: What is the typical process for installing a pulverizer beater?

A: Installation involves aligning the beater with the machines rotor assembly, securing it per the manufacturers design, and ensuring proper power connection based on whether its mechanically or electrically operated.Q: How does using this equipment benefit my industrial operations?

A: Utilizing a high-quality pulverizer beater enhances crushing efficiency, reduces downtime, and optimizes energy consumption, leading to lower operational costs and improved production rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Pulverizer Category

Shubh Micro Pulverizer No.2 Cgmp Model

Dimension (L*W*H) : L 66 * W 52 * H 60 Inch (in)

Equipment Type : SEMI AUTOMATIC

Power Source : Electric

Condition : New

Material : STAINLESS STEEL

Micro Pulverizer with Pneumatic System

Minimum Order Quantity : 01 Unit

Dimension (L*W*H) : Customizable as per model/configuration

Equipment Type : Micro Pulverizer with Pneumatic System

Power Source : Electric

Condition : New

Material : Mild Steel/Stainless Steel

Pulverizer with Pneumatic System

Minimum Order Quantity : 01 Unit

Dimension (L*W*H) : Approx. 1100 mm x 500 mm x 1300 mm

Equipment Type : Pulverizer with Pneumatic System

Power Source : Electric

Condition : New

Material : Mild Steel

Micro Jar Mill

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 570 x 420 x 440 mm

Equipment Type : Grinding/Milling Equipment

Power Source : Electric

Condition : New

Material : Mild Steel

Send Inquiry

Send Inquiry