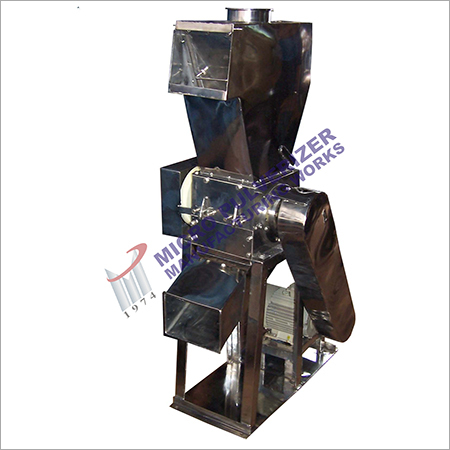

Shubh Micro Baby Pulverizer Cgmp

Shubh Micro Baby Pulverizer Cgmp Specification

- Equipment Type

- Micro Baby Pulverizer (CGMP Model)

- Condition

- New

- Material

- Stainless Steel

- Power Source

- Electric

- Power(W)

- 375 W

- Power Consumption

- 0.5 HP

- Dimension (L*W*H)

- 12 x 8 x 15 Inch

- Application

- Pharmaceutical, Laboratory, Grinding of Dry & Wet Pulverising

- Finishing

- Mirror Polished

- Contact Parts Material

- SS316 / SS304

- Capacity

- 10 to 30 Kg/Hr

- Automation Grade

- Semi Automatic

- Frequency

- 50 Hz

- Voltage

- 220 V

- Machine Weight

- Approx 28 Kg

- Discharge Size

- Up to 200 mesh

- Model

- Shubh Micro Baby Pulverizer

About Shubh Micro Baby Pulverizer Cgmp

Specification

| Capacity (Kg/Hour ) | 15 to 20 up to 300 mesh/ 50 micron |

| Power Consumption (HP) | 2 H.P. for Rotor 0.5 H.P. for Feeder |

| Warranty | 1 year |

| Speed (Rpm) | 9600 |

| No. Of Hammers | 6 |

| Brand | Shubh |

| Material | SS |

| Phase | Single Phase, Three Phase |

| Automatic Grade | Automatic |

Precision Pulverising for Multiple Applications

The Shubh Micro Baby Pulverizer excels in grinding both dry and wet materials, making it ideal for use in pharmaceutical labs and research facilities. Its fine discharge capacity up to 200 mesh supports thorough processing of raw ingredients. Engineers and researchers appreciate its compact footprint and mirror-polished surfaces for easy cleaning and hygienic handling in CGMP-compliant environments.

Energy-Efficient and Robust Stainless Steel Build

Engineered with stainless steel SS316/SS304 contact parts, this pulverizer ensures product safety and resistance to corrosion. Requiring only 375W of electric power, it offers high energy efficiency without compromising output. The solid build and compact dimensions (12 x 8 x 15 inches) make it perfect for labs with limited space while ensuring long-term, maintenance-friendly use.

FAQ's of Shubh Micro Baby Pulverizer Cgmp:

Q: What types of materials can the Shubh Micro Baby Pulverizer handle?

A: This pulverizer is designed for both dry and wet pulverising of a wide range of materials, especially in pharmaceutical and laboratory settings. It works effectively with powders, granules, and small solid substances requiring fine grinding.Q: How does the semi-automatic operation of this model benefit users?

A: The semi-automatic operation streamlines the pulverising process while maintaining user control, resulting in consistent product output and minimizing manual intervention. This makes it easy to operate for both experienced professionals and newcomers in laboratory or industrial setups.Q: When should this equipment be considered for use in laboratories?

A: The Shubh Micro Baby Pulverizer is best used when precise, small-batch grinding is needed, especially for research, formulation development, or quality control purposes in the pharmaceutical or scientific sectors.Q: Where is this pulverizer manufactured and can it be exported?

A: This model is manufactured in India and is available for export through established exporter, manufacturer, and service provider channels, ensuring reliable support and global accessibility.Q: What is the process for achieving fine discharge size up to 200 mesh?

A: Material is fed into the pulverizer where it is ground using high-grade stainless steel components, then discharged through screens that allow for fine particle sizes up to 200 mesh, suitable for pharmaceutical processing.Q: What are the benefits of the mirror-polished SS316/SS304 contact parts?

A: The mirror-polished stainless steel ensures easy cleaning, resistance to contamination, and compliance with CGMP standards, making it well-suited for pharmaceutical applications requiring high hygiene.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Pulverizer Category

Gravity Feeding Micro Pulverizer

Minimum Order Quantity : 01 Unit

Equipment Type : Gravity Feeding Micro Pulverizer

Material : Mild Steel

Condition : New

Power Consumption : 3 to 7.5 HP

Dimension (L*W*H) : 1500 x 600 x 1200 mm

Pulverizer with Pneumatic System

Minimum Order Quantity : 01 Unit

Equipment Type : Pulverizer with Pneumatic System

Material : Mild Steel

Condition : New

Power Consumption : 5 HP (approx. 3.7 kW)

Dimension (L*W*H) : Approx. 1100 mm x 500 mm x 1300 mm

Screen Sieves Micro Pulverizer

Minimum Order Quantity : 01 Unit

Equipment Type : Micro Pulverizer Screen Sieve

Material : Stainless Steel / Mild Steel

Condition : New

Power Consumption : Depends on pulverizer machine

Dimension (L*W*H) : As per machine model / Drawing

Crusher Micro Pulverizer

Minimum Order Quantity : 01 Unit

Equipment Type : Micro Pulverizer

Material : Mild Steel

Condition : New

Power Consumption : 37.5 kW

Dimension (L*W*H) : 900 x 600 x 1200 mm

Send Inquiry

Send Inquiry