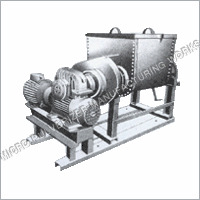

Sigma Kneader

Sigma Kneader Specification

- Type

- Sigma Kneader

- Material

- Mild Steel

- Computerized

- No

- Frequency (MHz)

- 50 Hz

- Size

- Standard/Customizable

- Width

- Variable as per model

- Dimension (L*W*H)

- As per model specifications

About Sigma Kneader

Sigma Kneader

We are considered to be one of the most profound and prominent manufacturers and exporters of Sigma Kneader. The kneader is widely appreciated in the market for its remarkable features like optimum performance, longer service life and hassle free operation. We also export the machines in foreign countries such as USA, Australia and Malaysia in order to gain more acceptance in global market. The Sigma Kneader finds usage in many industries such as food, pharmaceutical and chemical industry for the purpose of mixing materials.

Robust Mixing for Diverse Applications

Sigma Kneaders are meticulously engineered using mild steel, offering exceptional strength for industrial mixing tasks. Their customizable sizes and adaptable widths accommodate a spectrum of materials, from dough to adhesives. Suited for manufacturers seeking durable, high-performance blending solutions.

Tailored to Your Process Needs

Each Sigma Kneader is available as per standard or custom specifications, ensuring compatibility with your operational space and production requirements. This flexible approach allows industries to efficiently integrate the kneader into existing processes with minimal adjustments.

FAQs of Sigma Kneader:

Q: How does a Sigma Kneader function in industrial processes?

A: A Sigma Kneader uses specially designed sigma-shaped blades rotating at different speeds to thoroughly mix, knead, or blend high-viscosity materials. The robust mild steel construction ensures longevity and resistance during demanding operations.Q: What materials can be processed using this Sigma Kneader?

A: This kneader is suitable for a wide range of viscous substances, including dough, adhesives, rubber compounds, and specialty chemicals, thanks to its durable mild steel and customizable design.Q: When should I choose a standard or customized Sigma Kneader?

A: Opt for a standard model for general processing needs, while a customized kneader is recommended when you have unique size, width, or processing capacity requirements to fit specific applications.Q: Where is the Sigma Kneader manufactured and exported from?

A: These Sigma Kneaders are manufactured by a leading exporter, manufacturer, and service provider in India, supplying high-quality equipment to clients globally.Q: What is the typical usage process for the Sigma Kneader?

A: Material is loaded into the kneader chamber, where sigma blades rotate on a 50 Hz frequency, effectively blending the contents. The process is manual as the machine is non-computerized, allowing operators to monitor and control mixing duration and consistency.Q: What are the benefits of using a non-computerized Sigma Kneader?

A: A non-computerized Sigma Kneader offers reliable performance with simpler controls, reduced maintenance, and greater operational stability, making it ideal for industries seeking straightforward, effective mixing without complex automation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry