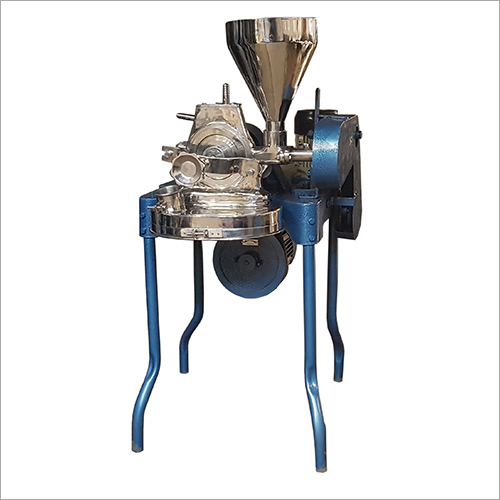

Side Feeding Micro Pulverizer

Side Feeding Micro Pulverizer Specification

- Equipment Type

- Side Feeding Micro Pulverizer

- Condition

- New

- Material

- Mild Steel / Stainless Steel

- Power Source

- Electric

- Dimension (L*W*H)

- 1200 mm x 800 mm x 1500 mm

Side Feeding Micro Pulverizer Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Delivery Time

- Days

- Packaging Details

- Wooden Packaging

- Main Export Market(s)

- Asia, Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, North America

- Main Domestic Market

- All India

About Side Feeding Micro Pulverizer

Side Feeding Micro Pulverizer

We have achieved high acclamation in the domain for offering a top-of-the-line gamut of Side Feeding Micro Pulverizer. At our robust infrastructure, we have with us state of the art machines and equipments to manufacture international quality machines. The range of micro pulverizer is appreciated by the clients for its remarkable features like high operational fluency, compact design and flawless performance. The Side Feeding Micro Pulverizer is suitable for grinding light weight materials.

Optimized Design and Durability

Built to the highest standards, the Side Feeding Micro Pulverizer features a compact yet sturdy construction with dimensions of 1200 mm x 800 mm x 1500 mm. Crafted from mild steel or stainless steel, it offers exceptional resistance to wear and corrosion, ensuring a long operational lifespan even under demanding conditions.

Efficient Performance and Versatility

This pulverizer operates on electric power, guaranteeing consistent performance for a range of materials. Its side feeding mechanism simplifies material input, improves safety, and supports uninterrupted processing. It is suitable for a variety of industrial applications, from grinding spices to handling chemical powders.

Trusted Indian Manufacturer and Exporter

As a reputed producer and exporter based in India, we ensure top quality and reliable after-sales support for every Side Feeding Micro Pulverizer. Our expertise as both manufacturer and service provider guarantees comprehensive assistance, from installation through maintenance.

FAQs of Side Feeding Micro Pulverizer:

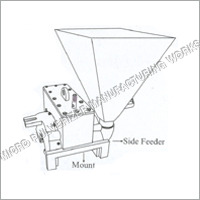

Q: How does the side feeding mechanism enhance the pulverizing process?

A: The side feeding system allows materials to be loaded smoothly into the grinding chamber, reducing the risk of spillage, ensuring even distribution, and improving processing efficiency compared to traditional top-feeding designs.Q: What materials can be processed using this Side Feeding Micro Pulverizer?

A: This machine is suitable for a broad range of materials, including dry spices, herbs, grains, chemicals, and pharmaceutical ingredients, making it versatile for various industries.Q: When is it beneficial to choose a stainless steel construction over mild steel?

A: Stainless steel is recommended when processing corrosive or food-grade materials due to its enhanced resistance to rust and contamination, ensuring product safety and machine durability.Q: Where is this equipment commonly used?

A: The Side Feeding Micro Pulverizer is widely used in pharmaceutical, chemical, agro-industrial, and food processing plants across India and in international markets.Q: What is the process for operating and maintaining the pulverizer?

A: To operate, connect the equipment to a compatible electric supply, load materials via the side feeder, and monitor the process. Regular cleaning, lubrication, and inspection of moving parts ensure optimal performance and longevity.Q: What are the key benefits of using this pulverizer for industrial applications?

A: The main advantages include efficient size reduction, minimal material loss, reduced manual handling, high throughput, and reliable, low-maintenance operation, all contributing to improved productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Micro Pulverizer Category

Liner Micro Pulverizer

Minimum Order Quantity : 01 Unit

Material : Stainless Steel

Equipment Type : Liner Micro Pulverizer

Condition : New

Dimension (L*W*H) : 1200 mm x 800 mm x 1800 mm

Power(W) : 3000 W

Gravity Feeding Micro Pulverizer

Minimum Order Quantity : 01 Unit

Material : Mild Steel

Equipment Type : Gravity Feeding Micro Pulverizer

Condition : New

Dimension (L*W*H) : 1500 x 600 x 1200 mm

Power(W) : 2200 to 5600 W

Micro Jar Mill

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Equipment Type : Grinding/Milling Equipment

Condition : New

Dimension (L*W*H) : 570 x 420 x 440 mm

Power(W) : 0.25 HP motor

Coal Pulverizer

Material : Mild Steel

Equipment Type : Coal Pulverizer

Condition : New

Dimension (L*W*H) : 500mm x 750mm x 900mm

Power(W) : 12000 W

Send Inquiry

Send Inquiry